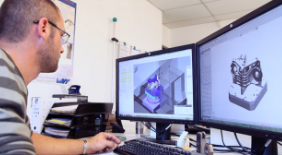

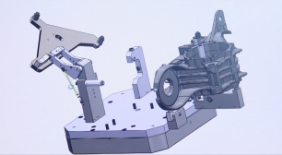

- Definition of needs

- Generation of specifications.

- Design and detailed design.

- Production files

We offer our customers turnkey services, accompanying them through the entire process, from project design to on-site installation. Every step is carefully managed by our extensive mechanical know-how.

-

DESIGN

-

MACHINING-WELDING

We propose end-to-end machining and welding services for boiler-making,

metalwork, ironwork and industrial sheet-metal work.

We work with steel, stainless steel, aluminum, bronze and brass.

We ensure full document coverage for the more sensitive workpieces with:

– Welding logbook,

– PQR (Procedure Qualification Record for welding: NF EN 15614 or ASME),

– WPQ (Welding Operator Performance Qualification: NF EN 287-1 or ASME),

– Non-Destructive Testing by COFREND 2 qualified staff,

– Inspection during manufacturing by outside body.

-

MACHINING

The Gami Group has an extensive set of machines including numerical control lathes, horizontal and vertical axis machining centers, numerical control fixed table milling machines, internal, external and plane cylindrical grinders, 3D test benches and overhead traveling cranes of up to 10 tons.

-

PAINTING

The Gami group is assisted by a group of partners specializing in

technical paint application.

Our partners are specialists in anticorrosion treatment and the

application of industrial paint in liquid and powder form.

They specialize in work on prototypes, small and medium runs, offering

quality, reactivity and adaptability to suit your needs.

Thanks to the diversity of our partners and their facilities, we can address

almost any request for technical coatings (powders, multicoated liquids,

sandblasting, shot blasting, metallization with copper, aluminum or zinc/aluminum, rilsanization,

etc.).

-

ASSEMBLY, DEFINITION, TESTING

Our machining department is benefits from a 6,000 m² surface area dedicated to assembly, definition and testing. Our mechanical and automation departments have the means necessary to guarantee you that their experience in the assembly and definition of your products will be carried out to the highest possible quality standards and in strict alignment with your specifications.